In modern industrial production and logistics transportation, the choice of bundling materials is crucial. Although traditional metal strapping is strong, it has problems such as heavy weight, easy to rust, and difficult to recycle. In recent years, Composite Corded Strapping has gradually become a new choice for industrial bundling with its excellent performance and environmental protection characteristics.

Ⅰ. Advantages of Composite Corded Strapping

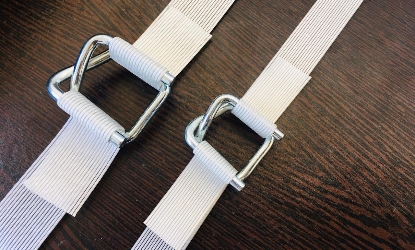

1. High strength and durability: Composite Corded Strapping is made of high-strength polyester fiber with extremely high tensile strength and impact resistance. It can withstand great tension and ensure the stability of the bundle during transportation and storage.

2. Corrosion resistance: Compared with metal strapping, Composite Corded Strapping is not affected by environmental factors such as moisture and salt spray, is not easy to rust, and has a longer service life.

3. Environmental protection: Polyester materials are easy to recycle and reuse, reducing pollution to the environment. At the same time, Composite Corded Strapping is lighter in weight, reducing energy consumption during transportation.

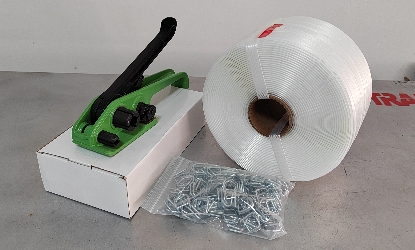

4. Convenient operation: Composite Corded Strapping is easy to cut and tie, and can improve work efficiency whether it is operated manually or using an automatic baler.

5. Wide range of applications: From logistics and transportation to agricultural storage, from industrial manufacturing to daily packaging, Composite Corded Strapping can provide reliable bundling solutions.

Ⅱ. Application cases of Plastic Strapping

1. Logistics and transportation: In the logistics industry, Plastic Strapping is often used to bundle pallet goods to ensure the stability and safety of goods during transportation.

2. Agricultural storage: In the agricultural field, Plastic Strapping can be used to bundle bales, feed bags, etc. to prevent loss and contamination.

3. Industrial manufacturing: In the manufacturing industry, Plastic Strapping can be used to bundle large mechanical equipment or parts to ensure that they are intact during transportation and storage.

4. Daily packaging: In daily life, Plastic Strapping can also be used to bundle large items such as furniture and electrical appliances for easy handling and storage.

Ⅲ. Economic Analysis of Plastic Strapping

Although the initial cost of Plastic Strapping may be slightly higher than that of traditional metal strapping, its durability and low maintenance cost make it more economical in the long run. The lightweight characteristics of Plastic Strapping also help reduce transportation costs, further reducing overall logistics costs.

Ⅳ. Environmental significance of Polyester Composite Strapping

Today, with the increasing awareness of environmental protection, the environmental protection characteristics of Polyester Composite Strapping are particularly important. It not only reduces the dependence on metal resources, but also is easy to recycle and reuse, reducing the burden on the environment. Choosing Polyester Composite Strapping is not only a guarantee of product quality, but also a responsibility to the environment.

Ⅴ. Conclusion

Polyester Composite Strapping is gradually replacing traditional metal strapping with its excellent performance and environmental protection characteristics, becoming a new choice for industrial bundling. Whether in logistics transportation, agricultural storage or industrial manufacturing, Polyester Composite Strapping can provide reliable, economical and environmentally friendly bundling solutions. With the continuous advancement of technology and the increase in market demand, the application prospects of Polyester Composite Strapping will be broader.

Whatsapp/Skype:+86 186 5726 7827

Monday to Saturday 9 am to 5 pm

E-mail:Sale7@bststrap.com

Send us your enquiry anytime!